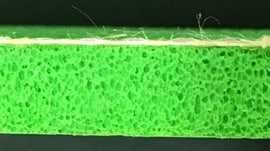

BSCT has perfected the technique to manufacture a web of multiple layers utilizing polyurethane, polyvinylchloride, acrylic and natural butadiene rubber chemistries. These specific compounded formulas are applied to a release paper web to produce films and composite materials; then using our unique coating technologies the coated web is carried through an oven to dry, fuse or cross link the formulas to provide an impervious smooth surface. The Transfer Coating Method affords great production versatility since it is adaptable to high and low thickness. These processing advantages combined with the highly desirable quality of the finished product, make the transfer coating method the most widely used coating technique for producing films, man made leather materials and other coated products.

- Our process enables up to 5 individual coatings

- Knife over Steel Roll

- Knife over Rubber Roll

- Paper or Textiles up to 80”

- 0.5 mils to 225+ mils

- Low Weight & High Weight

- Custom Color matched formulas

- Utilizing Paper & Roller Embossing Options

- Solvent & Water Based Chemistries

- P.V.C., P.U., Acrylic & NBR Chemistries

BSCT manufactures cast coated product 0.5 mils to 100 mils and up to 99” usable width for many industries including but not limited to Automotive, Marine, Military and Aerospace.